3 Effective Methods for Sterilizing 3D-Printed Surgical Guides

The sterilization methods applicable to a surgical guide are significantly determined by the material of the guide and even the technology used for its production.

In modern veterinary surgery, the combination of 3D-printed and traditional implants is gaining more traction, allowing surgeons to select the optimal solution based on the specifics of each case.

This hybrid approach is particularly beneficial in managing complex orthopedic conditions, where the combined use of standard implants and custom 3D-printed devices can enhance surgical outcomes and improve patient recovery.

Advantages of 3D-Printed Implants

3D printing technology has revolutionized the design and production of medical and veterinary implants, offering several advantages over traditional methods.

The Role of Traditional Implants

Traditional, standard implants have been used for many years, providing reliable solutions in numerous cases. Their advantages include:

A Practical Example of Using Standard and 3D-Printed Implants Together

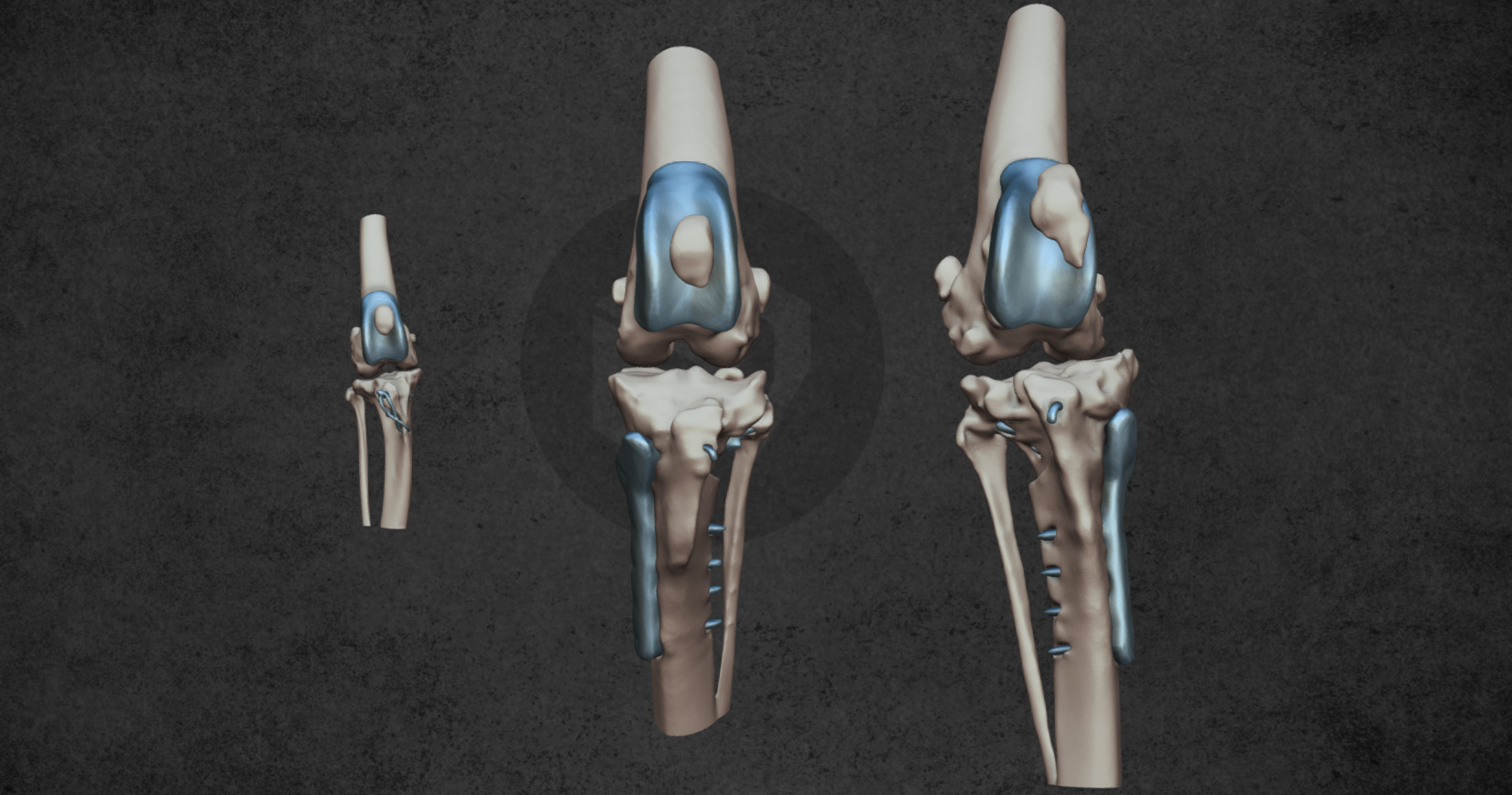

A Central Asian Shepherd dog named Luna suffered from two orthopedic issues in her left knee joint:

Due to the simultaneous presence of both conditions, the surgeons decided to treat them in a single procedure by combining different technologies.

The TPLO (tibial plateau leveling osteotomy) technique was used for the treatment of the CCL rupture, which is a well-established method for biomechanical stabilization of the knee joint.

For this procedure, standard implants were used to meet general surgical requirements.

However, for the correction of the patellar groove, a CT scan was used to model the affected bones, allowing for the creation of a custom 3D-printed TROCA patellar groove prosthesis that precisely follows the unique contours of the bone surface.

The TROCA prosthesis, made of a special titanium alloy, was designed with high precision to perfectly fit the surface of Luna’s bones and help prevent future luxations.

Why Was This Hybrid Solution Effective?

The surgery was successful, and Luna soon regained full use of her operated leg, demonstrating the benefits of a well-planned intervention.

One of the greatest advantages of using both traditional and 3D-printed implants is that there are no size limitations—thanks to personalized, custom-designed solutions, the technology can be applied to patients of nearly any size, from a Yorkshire Terrier to a Moscow Watchdog.

The Most Important Goal: Finding the Best Solution for the Patient

Our goal is to apply the most advanced technologies in veterinary care to provide innovative solutions.

Our product range includes the latest 3D-printed implants, prostheses, and surgical guides, which enhance the efficiency and safety of surgical procedures.

The case of Luna illustrates how combining traditional and 3D-printed implants can revolutionize veterinary surgery.

While standard implants offer proven biomechanical stability, custom 3D-printed components allow for precise, personalized solutions, ensuring perfect fit and long-term success.

The sterilization methods applicable to a surgical guide are significantly determined by the material of the guide and even the technology used for its production.

What are the main differences between modern, 3D-printed implants (3DI) and traditional, standard implants (CI)? Let’s go through them!

One of the most frequent orthopaedic deformation in small dogs is the dislocation of the patella. Patellar luxation is often a congenital, inherited disorder but it can also be caused by a trauma or an accident. With the help of 3D design and printing, we have created an implant which is considered exceptional worldwide. It is uniquely designed and manufactured for the femur of the given animal. We deliver this product together with anatomical models and surgical drilling guides.

Personalized implants

Personalized implants

Personalized implants

Patient-specific surgical equipment